A Clean Line of Light

Component based LED lighting allows the designer to create some truly unique projects, far beyond what can be done with the standard troffer/can lighting. Just take a look at the photo above this article, for an example; for more information on the referenced project, take a look at our homepage at https://klusdesign.com/. When looking to create that amazing look, the first question may be, where to begin? Our first question tends to be, where the LED lighting is going to be placed; is it going to be in direct view or is it going to be indirect view? For this article, we’re going to go with the first of those two options, and say it will be in direct view.

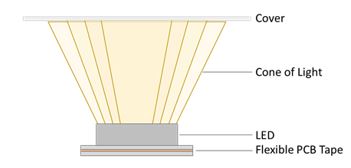

Here in the US, one of the more important features of LED lighting in direct view, is to achieve “a clean line of light” or in other words, no visible diodes from the LED tape light inside the fixture. Distilling this design constraint down to its basic components produces: Cones of Light and Covers. Expanding on these two characteristics gives us four elements of control when designing a fixture: Cover type, LED spacing, LED output, and Cover to LED spacing.

Cover type – There are many types of covers, each with specific design features for different applications. In this section, lenses and covers are used interchangeably. Generally, the two types of lenses include clear or frosted. Clear lenses can be immediately excluded from this discussion, since our focus is not to see the diodes. Of the frosted lenses, their material compositions and features may vary. The combination may be to maximize light diffusion, to minimize UV light damage/transmission, or to provide a low-cost option. Since our goal is to get a clean line of light, we’ll want to select a frosted cover that will maximize light diffusion.

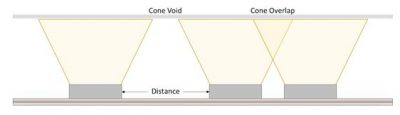

LED spacing (shown above) – This refers to the distance each individual diode, on the LED tape, sits from one another. This is provided in the LEDs spec-sheet or cut-sheet in a couple of different ways: as diodes per foot value or as a measurement (inches or mm). As shown above (left), there are two diodes spaced so that their cones of light do not overlap at the cover. They instead create a void of light at the cover. A higher diode per foot count (right) shows the cones of light overlapping at the cover. Overlapping cones of light at the cover will help produce the clean line of light look.

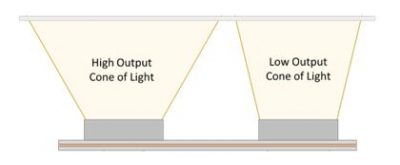

LED output – This can be measured in either a lumen per foot value or a wattage per foot value. In most cases, with LED tape lighting, the two are linked. Without getting into the physics of light and how a higher output affects the cone, we’re going to generalize from averages, that as the output level is increased, the cone of light will grow wider. As the output lever is lowered, the cone of light will recede.

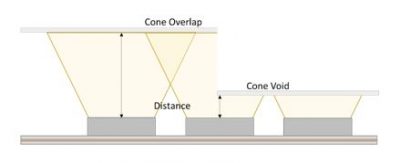

Cover to LED spacing – This refers to the distance the cover sits from the LED tape inside the LED fixture. From the image above, it can be shown that keeping all things equal (LED spacing, Cover type, and LED output) as you vary the distance from the cover to the LEDs the product of light can be modified from overlapping (left) to voids (right).

Now that we have presented the four elements that govern the clean line of light, we can provide our go to solution to achieve this look. Here at Klus, the cover that maximizes the light diffusion the best, is our Liger Frosted lens. Our highest diode per foot LED tapes, currently come with 81 diodes per foot (K-1820-HD-24V or K-1910-HD-24V), and they also have great output values. With three of the four elements optimized, using the above, a clean line of light can be achieved with any of our extrusions (extrusions the utilize covers). For projects that require crisscrossing lights, as shown at the beginning of this article, please contact our technical department for additional recommendations.