There are many benefits to anodizing LED extrusions. It offers increased protection in different ways. Aluminum has many possible chemical reactions it can undergo in different environments, and the anodization gives it a layer of protection from many of these potential issues. Potential issues caused by these reactions can vary from surface-level corrosion that causes a color change, to an interaction that can ruin the IP rating of the fixture and allow water to permeate the interior.

The anodized finish also gives the extrusions better resistance to scratches and similar handling damage. The surface can be easily cleaned. Another advantage that is a little less obvious is that the anodized finish offers a better surface for adhesives to adhere to, such as mounting adhesives and also the silicone gel used to seal the extrusions to achieve IP67.

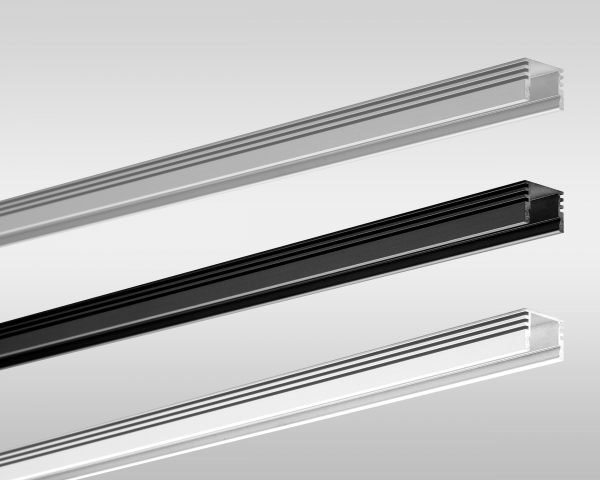

There are also multiple aesthetic benefits to the anodization process. The anodized finish gives the extrusion a matte silver finish that is more uniform than the finish a raw extruded aluminum would have. It also provides the option for different finish colors like the anodized black finish options we offer. In addition, if there is a desire for a color we do not offer, the anodized finish can easily be field-painted.

For these reasons, we recommend using an anodized extrusion for all applications where available! There are a few extrusion options we offer that have no anodized finish, but these are usually when the mounting design of the extrusion has it be fully recessed, like the TEKUS track and the KOZUS LED lighting extrusion. Our team here at Klus is always happy to answer any questions you may have about our products, and potentially make recommendations based on the details of your project.

Feel free to contact us at 772-569-6655, or through our technical email: engineering@Klusdesign.com.