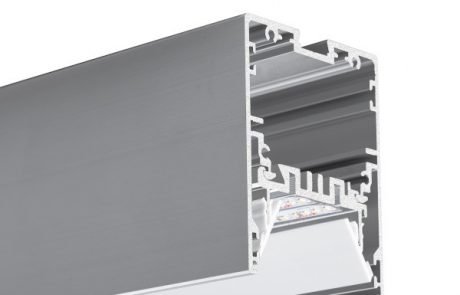

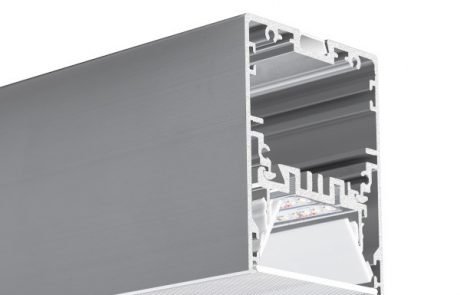

The KLUS MOD-50 LED lighting extrusion is used to build lighting fixtures with high light output, with space for power supplies and control electronics. With it the light can be directed up and down. The system solutions applied ensure easy assembly and disassembly of the lighting fixture while service is performed from below (it is possible to build LED lighting fixtures “from wall to wall”). There are two covers for this LED profile: standard frosted and prismatic with which a low glare factor UGR ≤ 19 can be obtained. MOD-50 lighting fixtures can produce a strong downward light beam (2 LED strips, 10mm wide or 1 LED current module 24mm wide) and an upward beam (1 LED strip, 10mm wide).

Click Here To Learn More about the KLUS MOD 50

The KLUŚ aluminum LED extrusion is the basic element used to build LED lighting fixtures. It performs an aesthetic and protective function for the LED strip housed inside. They are made of high-quality aluminum: raw, anodized, or painted from the RAL palette at the customer’s request. A feature of the LED extrusion system is the possibility of using a wide range of accessories such as covers, end caps, elements for mounting or connecting profiles to best adapt the LED fixtures built to individual needs.